Gold Plating To Improve Solderability of Materials

Two different examples:

|

|

| There are many applications where soldering a copper wire directly to a stainless steel surface would be valuable. Normally it would be very difficult or impossible to solder a copper wire to this 1/16" diameter Type 308 stainless steel rod. In this demonstration we will gold plate a portion of the end of the rod and then solder an 18 gauge copper wire to the gold plated stainless steel rod. We begin by lightly polishing the end of the rod using a metal polish to remove any oxidized material. |

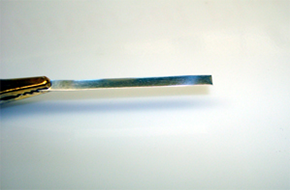

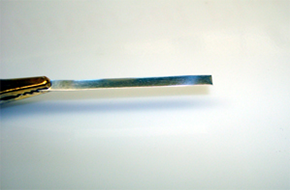

We have a client that wanted to plate with nickel and then 24K gold onto silver electrical contacts. For this demonstration we are using a 28 gauge pure silver strip that is ~3mm wide. We used an abrasive polishing cloth to remove any tarnish. We then used a little methyl alcohol to clean the part. It is now ready for the bright nickel plate. |

| Without nickel underplate |

Plating nickel underplate |

| A nickel underplate was not desired or required for gold plating this stainless steel rod. After polishing we simply cleaned with methyl alcohol. This rod is now ready for gold plating. Note: Activation of some stainless steel alloys is desirable and can be performed using Wood's Nickel Strike or TriVal Acid Gold Strike solution.

|

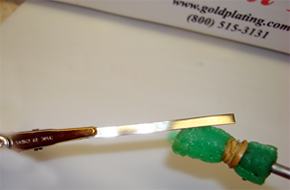

Since a nickel underplate was required for this application we applied a layer of Bright Nickel Plate directly onto the cleaned silver. |

| Gold plating the surface |

Gold plating the surface |

| The 24K Brush Gold was plated directly onto the stainless steel rod. We plated this rod end for about 30 seconds using the Universal Plater set at 4 volts. Because the stainless steel was freshly polished and clean activation was not necessary. If necessary stainless steel can be activated using Wood's Nickel Strike or some other hydrochloric acid based pretreatment.

|

Immediately after nickel plating we rinsed the surface and applied the 24K gold. Activation of freshly plated nickel is not normally required. We plated the end of this strip for about 30 seconds using the Universal Plater set to 4 volts, this applied approximately 20 micro-inches of hardened 24K gold plate. |

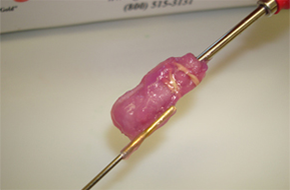

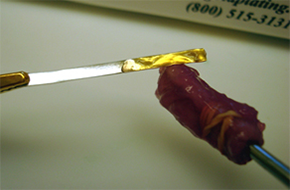

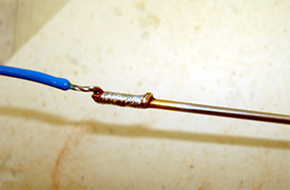

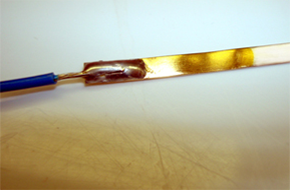

| Soldering copper wire to plated surface |

Soldering copper wire to plated surface |

| The gold plating process was successful and the copper wire was soldered to the gold plated surfaces using 60-40 resin core Sn / Pb 0.040 solder and a standard hand held soldering iron.

|

For this photo-demo we used the Universal Plater so that we could plate the silver strip with nickel without having to change the handle or sleeve. For applications that don't require electro-cleaning, activation or plating with 2 or more metals the PCB Plating Repair Kit would be an excellent choice.